Track and Trace

There is no one-size-fits-all solution for scanning or verifying machine-readable symbols. Many applications get by with fast, reliable scanning of one-dimensional (1D) bar codes. Others require more sophisticated CMOS-based imaging systems capable of reading or verifying the quality of data-rich two-dimensional (2D) stacked symbols, Data Matrix codes, or optical character recognition (OCR) fonts.

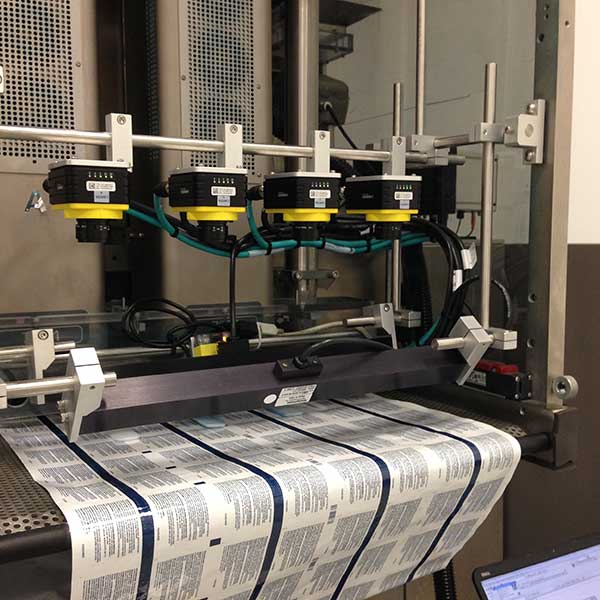

Combining expertise in machine vision, motion control and machine design, Vision and Control Systems (VCS) is a leading full-service integrator of automated track and trace solutions. We deliver high-performance laser- or CMOS-based barcode readers capable of fast, accurate scanning of direct part mark (DPM) 1D and 2D barcodes, as well as OCR.

VCS engineers bring expertise in all symbologies, codes, and scanning hardware — no matter how high-speed or complex — to ensure that your track and trace system will accurately register every bar, space, cell, quiet zone, and character with maximum efficiency and reliability. Our know-how extends beyond track and trace functionality to include design, integration, and programming of advanced systems capable of detecting misoriented or missing packages. These systems range from single-point readers on a conveyor belt to scan tunnels.

Verification and Validation

VCS specializes in measuring the quality of bar codes, OCR, and other data strings to predict readability (verification) and in evaluating the format and content of a code, label, or both (validation). Our validation capabilities also encompass statistical process control (SPC) to automatically detect dropping inkjet levels, as well as other performance issues, for bar code printers, dot peen code application systems, and additional DPM systems.

Our capabilities also encompass unique 360-degree reading solutions, which can read and verify bar codes or labels on round containers traveling at high speeds — regardless of orientation. Comprising multiple barcode readers mounted in a circle around the production line, these noncontact verification systems can rapidly scan a wide range of 1D and 2D machine-readable codes as well as perform OCR on virtually any curved surface. Our 360-degree reading solutions can provide a visual audit record to limit risk in highly regulated industries, such as food and beverage, consumer packaged goods, (CPG), and particularly pharmaceuticals. Track and trace applications for pharma encompass reading or verifying lot codes, expiration dates, unit device identification (UDI), and kit assembly.

VCS can design these and other bar code scanning systems to support application standards such as GS1 and ISO/IEC, as well as the FDA’s 21 CFR Part 11 regulation.

Whom We Work With

- Cognex technology: A platinum-level Cognex partner system integrator, VCS is fully trained and authorized on Cognex’s In-Sight, VisionPro, and Designer platforms.

- Machine vision systems from Keyence, SICK, LMI Technologies, and Banner

- Robot integration from Universal Robots and FANUC

- PLC and HMI hardware from Rockwell Automation, Siemens, and AutomationDirect, as well as Beckhoff, for whom we are a certified system integrator

Familiar with these and many other proven hardware suppliers, VCS engineers fully test and optimize your machine vision system to ensure that it performs to your specifications. The breadth of our expertise allows us to bring the resources and know-how to meet and exceed virtually any challenge in machine vision.

VCS services and support cover the U.S. East Coast and beyond, with locations based near New York City and the Southeast’s emerging automation hub in South Carolina. We welcome customers to visit our locations at any time for planning, progress updates, and training. With VCS, you’re never far from your partner in automation solutions.

Contact us today to learn how VCS can make vision and control systems work for you. Dial 908-686-9400 or email us at sales@v-csystems.com.